Discover The Source of our Tanzanite

Full Traceability. Total Integrity.

Most retailers can’t tell you where their gemstones came from—or who cut them. We can.

Every tanzanite we sell is fully traceable to its source in Merelani, Tanzania. From the mine to the master cutter to the final piece, we oversee every step of the journey—ensuring total transparency, ethical practices, and exceptional quality.

We work exclusively with responsibly mined tanzanite, under safe working conditions and environmentally sound principles. Each gem or jewelry piece accompanied by our certificate is guaranteed to have been mined and polished in accordance with the Tucson Tanzanite Protocol, UN ILO Declaration on Fundamental Principles and Rights at Work (1998) & Tanzanian employment law.

MERELANI, TANZANIA

MINE SITE

HERE IS EXACTLY WHERE YOUR TANZANITE COMES FROM

Tanzanite Direct guarantee the origin of every gemstone we offer—along with its authenticity, traceability, and conflict-free, ethically-sourced status.

(Latitude: -3.5615° Longitude: 36.9622° E)

your jewel's journey

Tanzanite’s First Glimpse of the World

It’s incredible to think that after more than 65,000 years hidden deep beneath the Earth, mining marks the moment tanzanite sees the light of day for the very first time—and begins its journey to you.

MINING TANZANITE

#1: GOING UNDERGROUND

Going underground into a tanzanite mine is an unforgettable experience—some shafts plunge as deep as 800 meters, making them the deepest colored gemstone mines in the world.

#2: Where to Dig?

Early miners found tanzanite on the surface, but those days are long gone. Today, deep tunneling is guided by geological mapping. Sophisticated infrastructure provides ventilation, water systems, and safety measures to support miners as they delve deeper.

#3: Opening the Rock Face

Controlled blasting opens up areas of the rock face. Skilled workers then perform a “face pick” to carefully remove tanzanite crystals by hand— using nothing more than a pulley and bag system to send the stones to the surface, as shown here.

#4: Big Finds Are Rare

While large tanzanite crystals are occasionally discovered, they are the exception, not the rule. Most extractions yield much smaller stones, often in fragmented pieces.

#5: Surface Washed and Sent for Sorting

Once on the surface and given a quick wash, the stones are sent to the sort house via conveyor belt.

#6: Exposing the Crystal Core

Back on the surface, the crystals undergo a process called cobbing, where graphite and host rock are removed from the crystals with small hammers. This precise work reveals the rough stones' natural beauty and prepares them for grading.

#7: Separating the Exceptional from the Ordinary

Then comes sorting—where each stone is graded by color, clarity, and size.

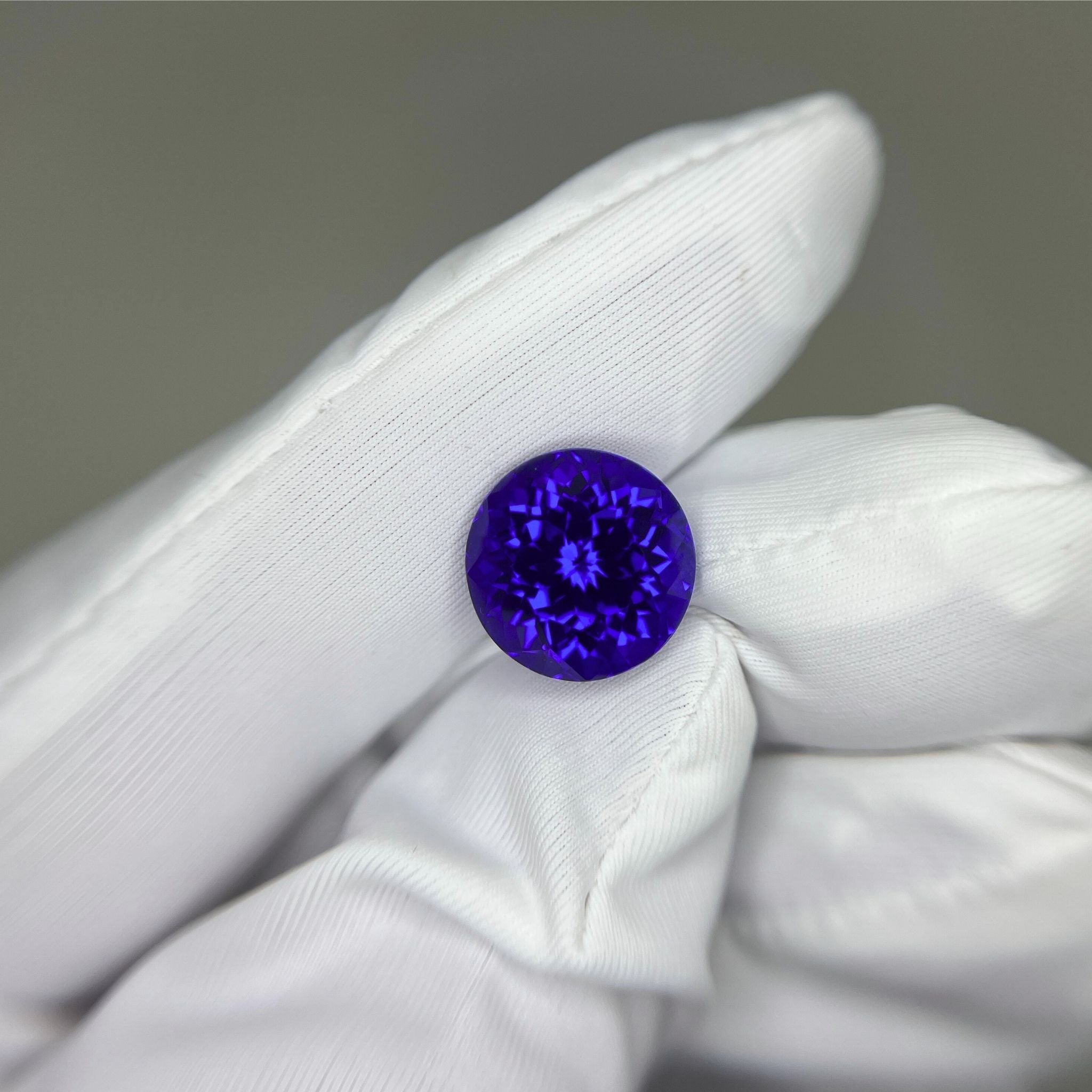

#8: CUTTING & POLISHING

Each stone is cut and polished in-house by our master cutters. After polishing a small window to assess clarity, the stone is secured on a stick and shaped on a spinning wheel, facet by facet. The process is 100% manual and can take days.

#9: Grading & Trading

Once polished, the tanzanite is graded by our in-house gemological team for color, clarity, cut, and carat weight. After grading is complete, the gem will either be sold to one of our trusted wholesale clients or set into one of our signature jewelry pieces.

Or maybe it will be special enough to be handpicked for you!

Featured collection